Every operation has its specifics, whether it is zinc plating plants, foundries, glassworks, or breweries. We handle them all. Specializing in particulate filtration equipment since 1968, our clients never leave us.

We specialize in solid particulate filtration equipment

We will design the right filter for you based on the level of dust, source of pollution, and operating conditions.

Of course, we also consider meeting emission limits.

Click on the image for animation

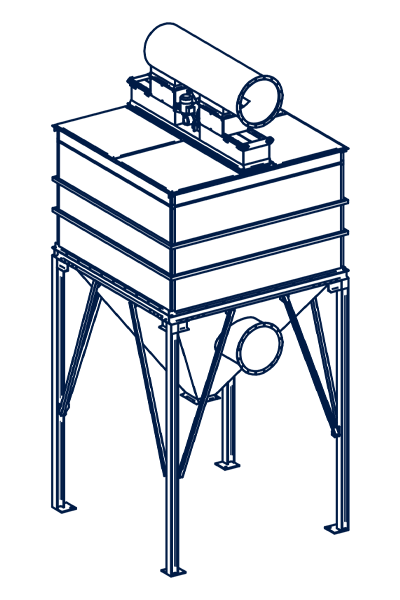

Pulse Jet Air regeneration equipment (mixing part, outlet part, and pressure air tank with nozzles)

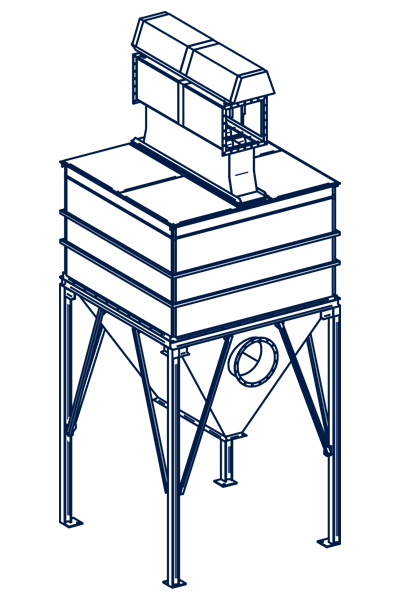

Backflush regeneration equipment with outlet part

Filtration Area up to 200m2

Filtration discharge can be either conical or trough-based as needed.

Even machines require regular care. And regeneration is essential. In our equipment, cycles of filtration and regeneration alternate, removing separated layers of dust from the surface of the filtration textile. We aim to maintain the pressure loss of the filtration equipment and thus the flow rate of filtered air at the project’s specified operational value.

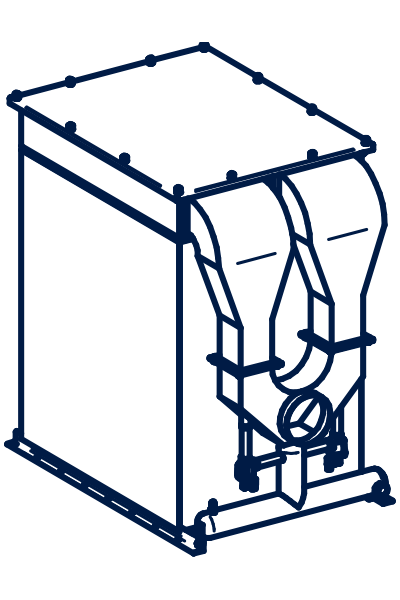

It operates on the principle of drawing atmospheric air from the surroundings. The filter cleans under negative pressure, where, after opening the ‘flushing’ and closing the ‘output’ flap, the filtration insert of the regenerated part of the filter (chamber) is reverse-flushed.

Advantages

Disadvantages

Utilization

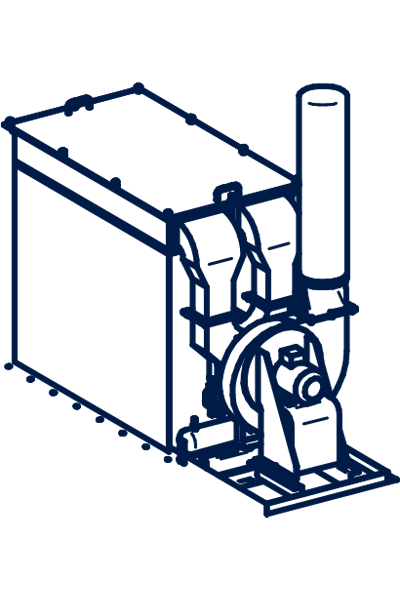

It operates on the principle of an ejector (Venturi nozzle). The mixture of pressure and suction air achieves a dynamic impact on the filtration insert while simultaneously causing reverse airflow through the textile. This removes the separated dust from the surface of the textile.

Advantages

Disadvantages

Utilization

Everything has its time. First, we fine-tune the conditions of collaboration,

and then we work diligently to ensure the perfect outcome.

We assess the operation parameters, your requirements, and the technical possibilities of the facility.

We provide an offer and create a proposal, which we consult with you throughout the project.

We manufacture or repair the filtration equipment. We install it and train your personnel.

APF Praha a.s.

Písnická 541,

142 00 Praha 12- Kamýk

IN: 26150671

VAT: CZ26150671

Copyright 2022 APF a.s.